Services

Custom Machine Creation | EX31 Industrial Automation Company Virginia

Custom Machine Creation | EX31 Industrial Automation Company Virginia

At EX31 Industrial Automation company Virginia, we provide factory machinery solutions in both Virginia and all across the great USA. We provide a host of solutions to meet most every need. We blend in our strengths for mechanical design with electrical controls to achieve a unique offing of factory automation services. Our portfolio of vendors that we partner with allows us to offer our customers the best possible technology solutions for factory automation Virginia. Our commitment to you is to utilize those vendors and avoid re-inventing the wheel whenever possible.

Custom Machine Creation

We are a team of passionate gear heads at heart. Our first goal in every factory automation Virginia engagement is to figure out if there is an off the shelf solution to meet your needs. When there isn’t, EX31s team of machine creators will thrive to meet the design needs with excellence every time. This is why we are passionate about cross training our team in both mechanical and electrical engineering fields. We know that by doing this, it offers our customers the most comprehensive solutions to their factory industrial automation company Virginia needs.

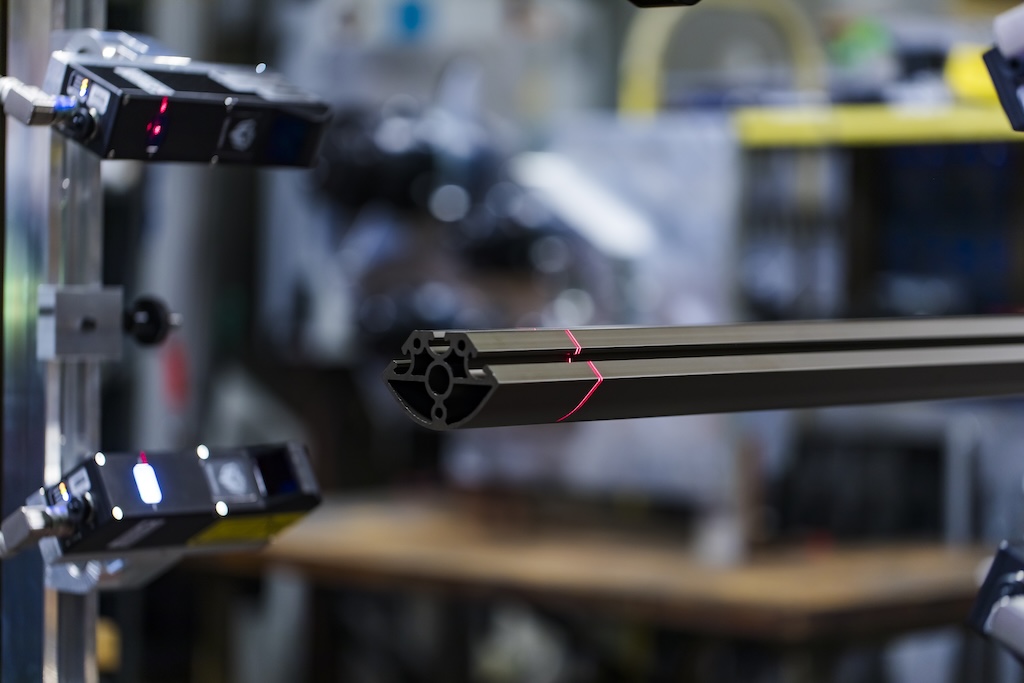

Vision and Inspection

Vision within the factory automation field is so important is has become part of our culture at EX31 Industrial Automation. We constantly review most major vision equipment suppliers and formulate the best offerings for our customers needs. This includes using artificial intelligence tools in our vision offerings, and working with the best in the industry to create the best automation solutions. Our Arch Inline Quality, inline vision inspection system is a great example of a technology approach not turned into a complete factory automation system solution, born right here in the Virginian Commonwealth. Have a challenging inspection project? Give us a call today and we will either be able to offer you a solution, or connect you with the right technology to meet your vision and inspection needs.

Vision within the factory automation field is so important is has become part of our culture at EX31 Industrial Automation. We constantly review most major vision equipment suppliers and formulate the best offerings for our customers needs. This includes using artificial intelligence tools in our vision offerings, and working with the best in the industry to create the best automation solutions. Our Arch Inline Quality, inline vision inspection system is a great example of a technology approach not turned into a complete factory automation system solution, born right here in the Virginian Commonwealth. Have a challenging inspection project? Give us a call today and we will either be able to offer you a solution, or connect you with the right technology to meet your vision and inspection needs.

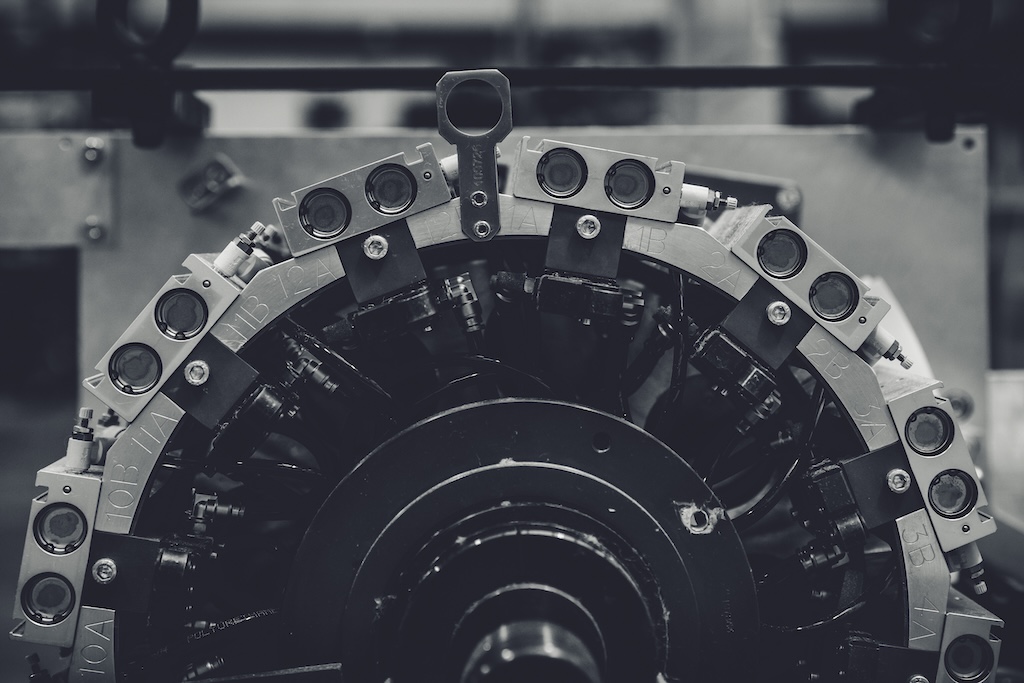

Continuous Motion Machinery

EX31 Industrial Automation company Virginia can be in a different technology class all by itself. It is arguable that Richmond VA is the home base in the world for all things related to high speed manufacturing machinery. German and Italian engineers will argue that with me forever, but we will stay opinionated about it and enjoy the competition. At EX31 Automation, we like to go fast, and the best way for our customers to really have a competitive advantage is to go faster than their competition. Continuous motion machinery enables you to do this. Typically these types of applications tend to be very specific and in niche markets. EX31 Automation has a developed many solutions in the continuous motion factory automation field utilizing alternative design principles to keep the cost entry point for custom machinery much more competitive. This real fit for this type of application is when you are trying to make more than ~300-400 parts per minute in a streamlined process. If you have a manufacturing process that is currently an indexing motion type, or if you want to take your existing rotary process and go faster, engage our team today and let us see if we can help you win big.

Reverse Engineering

Do you have a project where you need to re-create a custom machine or replicate a manufacturing process? Fantastic, our team of engineers and technical experts can assist you with going through your existing process, identifying the pain points if any, and offering you a new and improved solution. We constantly invest in the latest technologies to support reverse engineering efforts for factory automation, including 3D scanning systems that allow us to quickly capture legacy designs, and reverse engineer them to meet your factor industrial automation company Virginia needs.

Retrofits and Diagnostics

At EX31, our staff has a long history of retrofitting and improving the performance of your factory automation manufacturing equipment. We typically take a very systematic approach to first understanding current state of an automation system. Then from that initial analysis, we develop an improvement plan that you can decide how far you want to take forward. All to many times we come across machinery that needs some basic TLC, and many times it’s not due to lack of maintenance, but lost knowledge on how the original machine design was intended to function. Due to our experience in the custom machine creation field, we look at it thru the eyes of the original inventor, and can help you capture what needs to be changed to achieve higher OEEs (overall equipment effectiveness). Many times it is low hanging fruit that stems from time on machinery and knowledge gained that the original machine inventor was never able to capture. We take the time to listen to your factory automation operators and technicians and usually can recommend a solution that solves many machinery health problems quickly. Over the years we have gained a lot of respect on the factor automation floors because we not only design on machinery, but physically get involved with helping our customer on the floor achieve success.

Machinery Rebuilds

Do you have an older piece of equipment that needs some TLC. Our team of gear heads and controls experts can help you! At the bright young age of 12, our founder rebuilt his first automatic transmission. Little did he know that this desire to learn about complex mechanical system would take him down the road to running a automation company Virginia based. Putting new life into machinery is a passion of ours at the core. There is no machine to complex that we are not willing to work on and repair. Our reverse engineering skills also blend a nice support foundation and together with the machinery rebuild services are a winning combination to getting your factory automation needs met quickly and on budget.

Machinery Integrator

Need factory automation support for starting new machinery? EX31 Automation has the resources needed to support basic system commissioning. Our goal in providing machinery integration services is to spend the minimal amount of time in your plant. Yes, minimal amount. We really do not want to live in your facility. Our preference is to first build a machine that has proven its functionality prior to leaving our facility, then work in tandem with your trusted local, and local being the key, technical support contractors. It is usually in our customers best interest to work with their local support contractors, who already familiar with your specific safety procedures, and know the site staff. This also supports our core goals at EX31 Automation for building local site support at every business or manufacturing facility we build machinery for.

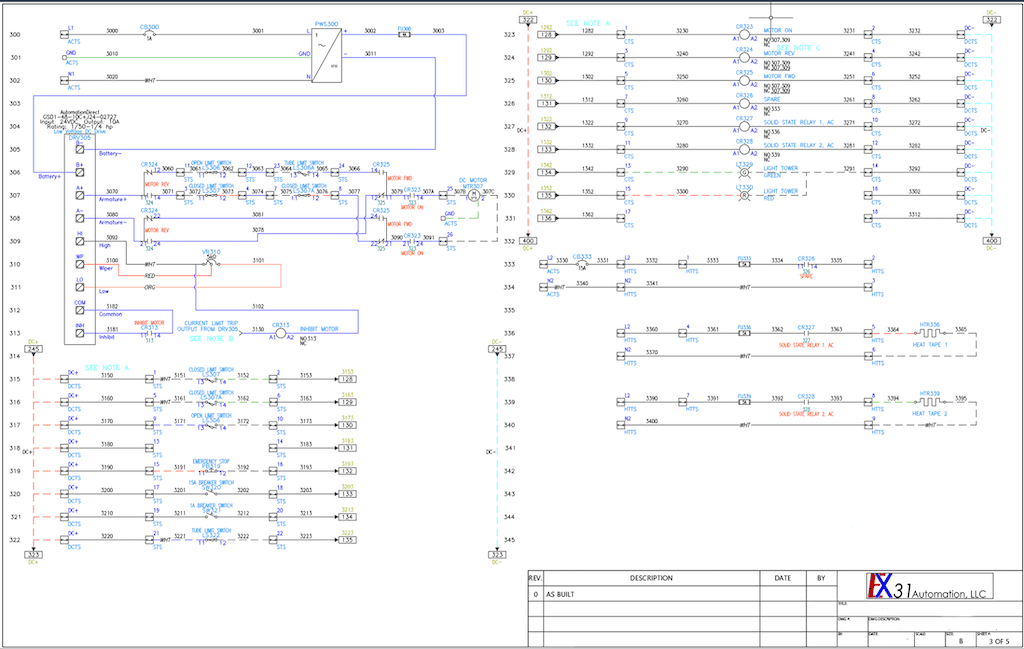

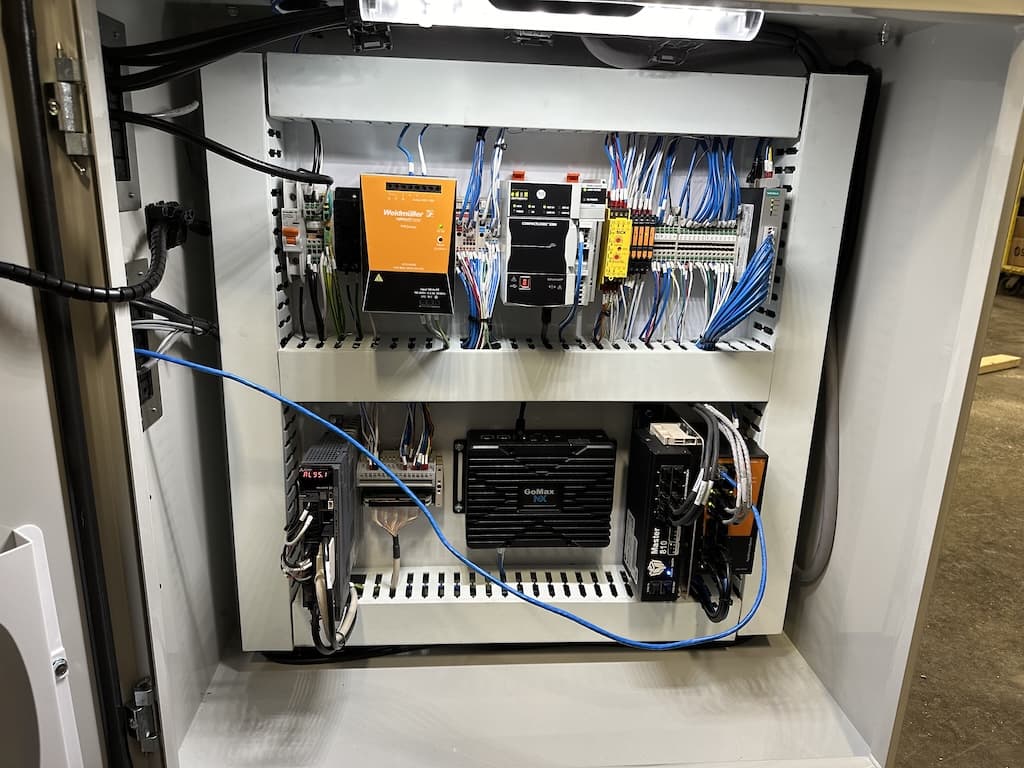

Electrical Panel Design

Our assembly team takes the upmost care in building high quality control panels. We utilize the leading industry tools for building panels that stand the test of time for your factory automation company Virginia needs. This includes a host of checkout procedures to ensure that each panel we deliver is serviceable, and has a clearly readable schematic.

PLC Controls

At EX31 Automation we offer a verity of PLC controls services. We cover brands such as Siemens, Allen Bradley, and Horner OCS to name a few. Our goal is to best align with what our customer are standardized on, and as needed we pull in additional controls platforms to meet the design criteria.

Our Process | How We Work

Free Quotation

Our process begins with your first engagement with out team. If needed this starts with a mutual non disclosure agreement to maintain the upmost confidentiality with our clients. Then we meet with either in person if you are close enough, or we can setup an online phone call. During this call we do our best to capture your needs statement, outline a basic approach and collect any necessary information needed to provide you our budgetary quote. Our free offer is to provide a basic CAD model of your project concept, and budgetary proposal within 5 business days.

Next Steps

After receiving our initial budgetary proposal, we typically request our customers engage us in the first phase of development. This phase allows us to create a more detailed focused quote where you get the benefit of a dedicated team of creators working on your behalf to deliver a refined proposal. During the process we engage our vendors for multiple proposals (RFPs) and gage if they will be a good technology fit for your application. This ensures that we have done our due diligence and you then have clear steps forward with detailed refined scope and cost. It also creates confidence that the solution we are proposing will be successful and provides you with necessary tools to start the next phase of the project.

Custom Automation Factory Solutions

Working on a new idea or upgrading existing machinery? Maybe you need a 3D model to help get those creative juices flowing? We are here to help you along the way and brain storm with you until we find that perfect alignment and solve your needs with precision. Our aim is to work with you as if we are your biggest supporter and help you achieve success for you and your team of manufacturers, engineers, operators and business owners.

Cost Effective Approach

Every factory industrial automation company Virginia project should have multiple phases if the timeline for implementation allows. It is just a good way of approaching a difficult situation where you are trying to balance quality, lead time to delivery, and overall cost. Your team at EX31 knows this all so well. We understand that factory automation projects can be very expensive. Small changes in the scope and missed details can mean the success or failure of a project, and the overall cost, including after implementation, has to be addressed in the development phase of a project. It’s not always clear what path to take when building a custom system. We prefer to run our projects in a very systematic approach and this in turn enables us to create the win for our customers.

Good Enough?

Good enough is not good enough. Our reputation of excellence is on the line. Our goal for you is for our work to speak for itself, and every factory automation system we create should be a solution that enables our customers to achieve success. We put a lot of care and time into everything we do, and have systems with guardrails in place to keep our quality of what we deliver at its best. Our engagement with you will always be professional and you can expect the upmost attention from our team servicing you machinery design and factory automation needs.

Availability & Service Areas

Factories up and down in the eastern US and all the way to the west coast have utilized our design services. Our business platform allows us to work remote when needed, and to support startups all across the US. Our office is open by appointment only, and we are typically available from 8am – 5pm Monday through Friday. Outside of the normal house, you can reach out team as needed on a project basis. You will have the project managers phone number and a pre agreed upon availability for supporting 24/7 operations. We do our best to ensure our systems function as intended before ever leaving our facility, and in this manner, we reduce the factory automation startup time for most applications. Many of our vendors offer quick turn around on custom parts, and in this manner we strive to get an A+ rating from you.

Frequently Asked Questions

Preliminary Cost

We have a proven method for capturing your initial request. This allows us to offer you a basic 3D CAD model and budgetary quote. After the budgetary, we figure out what the minimal cost to you should be for the labor needed to solve your particular application. This in turn allows us to create a refined proposal with realistic cost basis you can trust.

Do we cover Factory Automation Services Not Listed on Your Website?

Yes. We are however a custom machine builder. Single machine builds are expense, and we want you to get the most value out of an engagement with our team. If there is a solution that is already available from an OEM, we would ask you why that is not a first choice. Keep it simple, it can always get more complicated if needed.

Do we subcontract our services?

Depending on the size and scope of the work we perform, we may subcontract part of our services rendered. We have been in this industry for a number of years and have great working relationships with many vendors and even our competitors. Our focus is always on providing our customers with world class solutions, and we work with other world-class suppliers and leading technology companies to do this.

That said, we treat every project as requiring the upmost confidentiality. Be assured that we have safeguards in place to protect your IP utilizing the latest industry standards.

Are Your Factory Automation Solutions Unique?

If you are engaging us for a custom built factory solution, then it will be unique. Again, we don’t want to reinvent the wheel. If there is an existing technology, we will make the recommendation to pursue that as a first option. We would love the opportunity to help you with this, and many times, you end up spending the same cost to acquire that technology directly or indirectly thru us, with added benefit of our teams oversight.

Is There a Way to Reduce Custom Machinery Solution Entry Point?

We have many pre-agreed upon service rates and reduced parts cost with our suppliers. This along with limited overhead, and a multi phased approach to your factory automation solution keeps us very competitive to our competitors.

Next Steps?

You will hear this from us all the time. Next steps, milestones, goals, targets, etc., we have to have them, we will help you create them and together we will win. Everyone at EX31 loves to be a team player and bring their A-game every day. The best move you could ever make is to give us the opportunity to earn your respect and business.