Arch-I.Q.

Custom Machine Creation | EX31 Industrial Automation Company Virginia

At EX31 Industrial Automation company Virginia, we provide factory machinery solutions in both Virginia and all across the great USA. We provide a host of solutions to meet most every need. We blend in our strengths for mechanical design with electrical controls to achieve a unique offing of factory industrial automation company Virginia services.

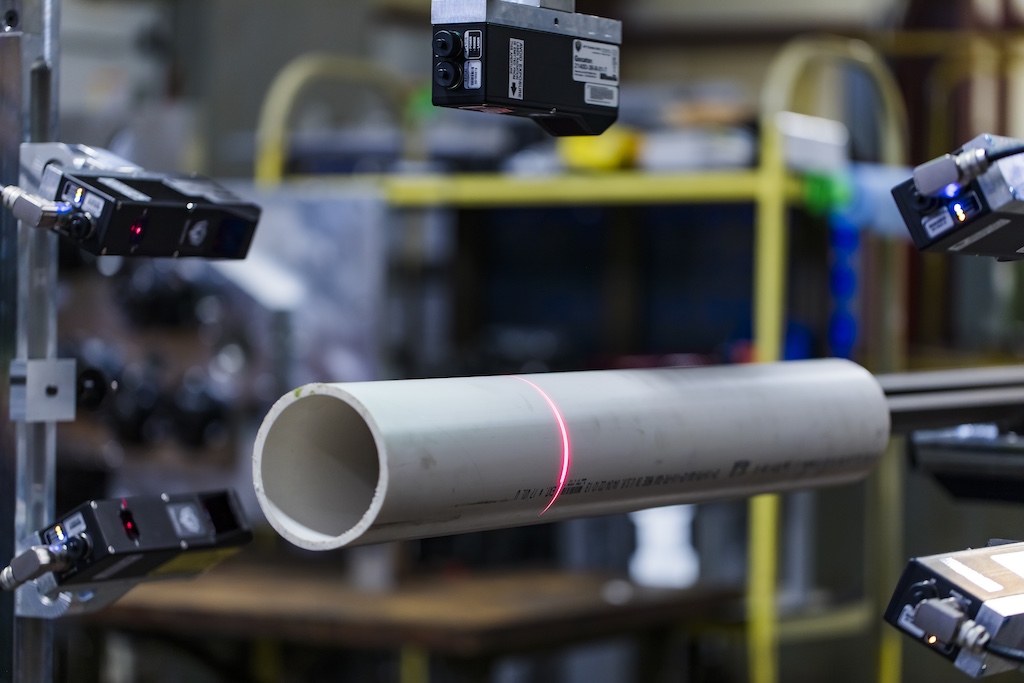

Our inline vision inspection system is no exception to the top quality solutions we create at EX31 Industrial Automation Company. Born out of a need for blending quality mechanical design principles, factory automation systems, and advanced controls, our Arch Inline Quality solution is the perfect fit for most every company that transports products on a conveyor and needs to inspect them. Our solution is of course not suited for every product, however if you have a need to measure critical dimensions, look for product defects or want to provide real-time feedback to your controls system, contact us today for a free consultation. If our team determines we may be able to provide you value, we will create a 3D CAD model and supply a budgetary quote to you within 5 business days.

What Is the Arch Inline Quality (Arch-I.Q.) Solution?

We are a team of passionate gear heads at heart. Our first goal in every factory automation Virginia engagement is to figure out if there is an off the shelf solution to meet your needs. When there isn’t, EX31s team of machine creators will thrive to meet the design needs with excellence every time. This is why we are passionate about cross training our team in both mechanical and electrical engineering fields. We know that by doing this, it offers our customers the most comprehensive solutions to their factory industrial automation company Virginia needs.

Why the Arch?

Our factory automation Virginia based solution has it roots in high-speed mechanical machinery design. Our approach has been to utilize the best design principles and take the simple approach first. What better way to do that than having a system that is rapidly configurable, and minimizes the modifications needed to your factory processing line. If you are extruding products, or running a dual edge tenor (DET) machine, chances are you have a shape product that at a minimum requires dimensional accuracy for quality fitment. Having our AIQ solution, that you can literally roll up to your factory line, will allow you to get started measuring and inspecting your products the first day you receive it.

Arch Platforms and Precision Frames

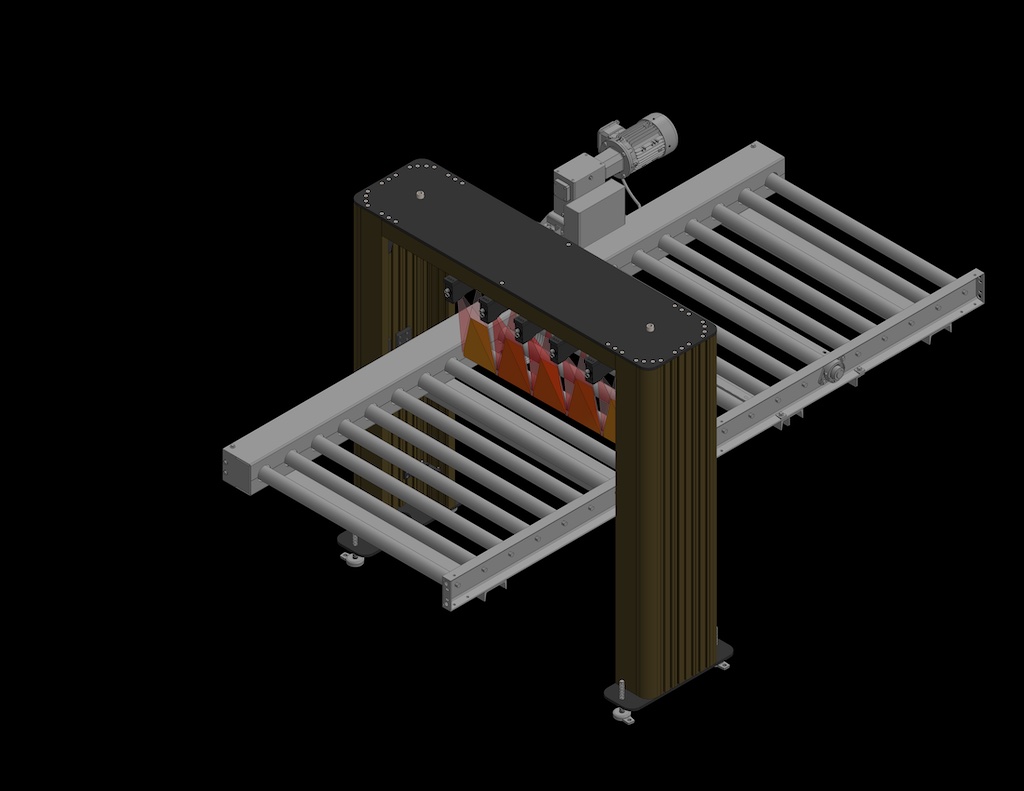

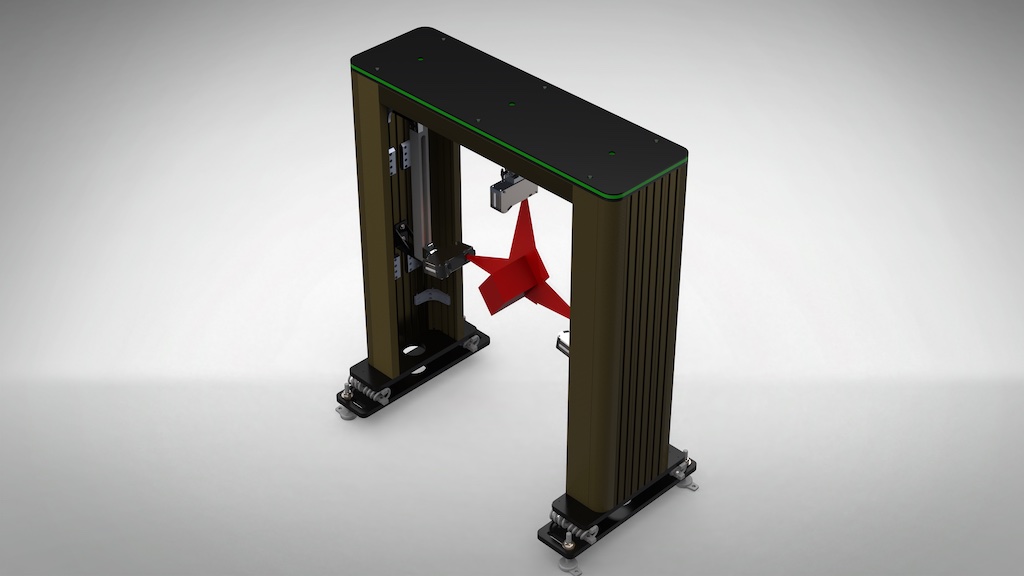

Our AIQ platforms utilize Precision frames for their core functionality. These frames come in two different flavors. The first system we recommend everyone starting with is the Universal Frame. This solution is typically sized by one of our vision engineers in the first engagement with you. The secondary reason for a universal frame is with clients who have higher verity shape products that they manufacture. The flexibility in this system, along with the planer control characteristics, outperforms all our competition.

If you have more than one identical system you need to install, we then recommend our Fixed Frame precision frame design. This system uses traditional key features to make virtually identical solutions from line to line and standardize a frame design that meets high production demands. Both systems allow you to swap the core of the inspection machine minimizing any downtime on your manufacturing lines. As long as access can be maintained to the inspection system, you can literally swap the precision frame in and out of the arch in about 5 minutes.

A-IQ Classic

The AIQ classic arch utilizes both Universal and Fixed Precision frames. It is built like an old streamlined locomotive. Utilizing the best in industry heavy duty framing components, this system can be configured to measure an object the size of a drinking straw all the way to a full sheet of plywood using the same system core configuration. We even have options for vibration isolation for harsh duty applications.

A-IQ Lite

The AIQ Lite arch utilizes both Universal and Fixed Precision frames. Its core is a heavy duty extruded frame skinned in your favorite color cover panels. Our standard is a stainless-steel finish, and this system has the nick name St. Louis Lite. This solution is by far the most economical approach when first getting started and allows our clients the most flexibility during development of a closed loop control system. The AIQ Lite vision platform is the best balance for an initial entry point and maximizing your return on a hardware investment.

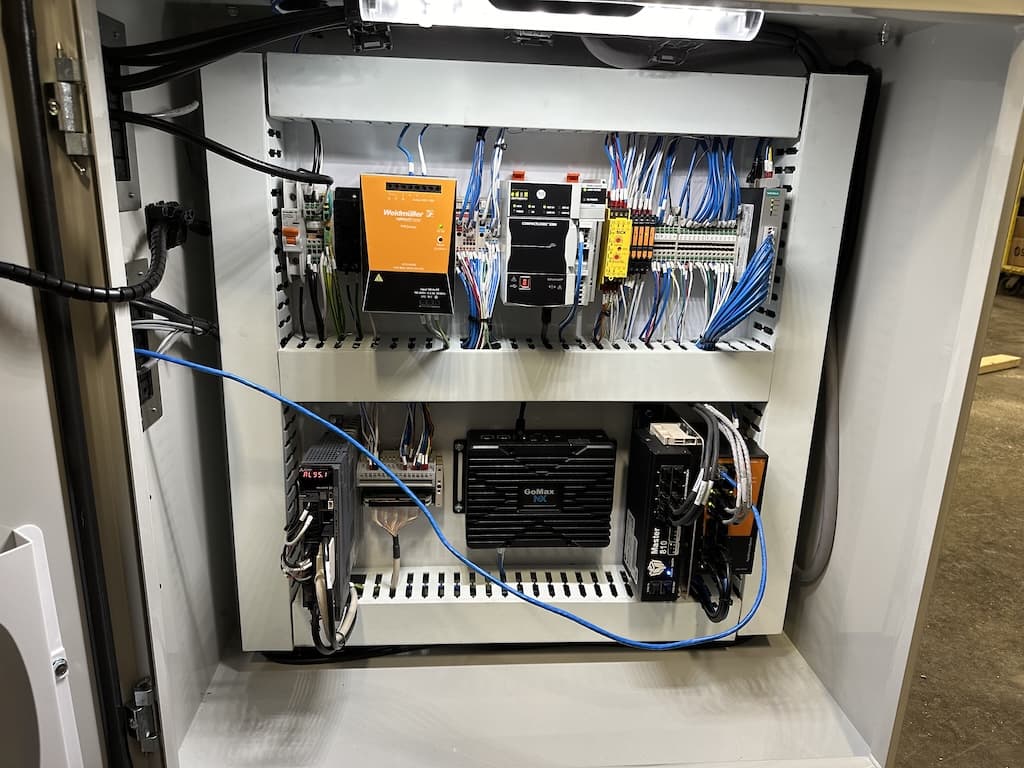

Controls Systems

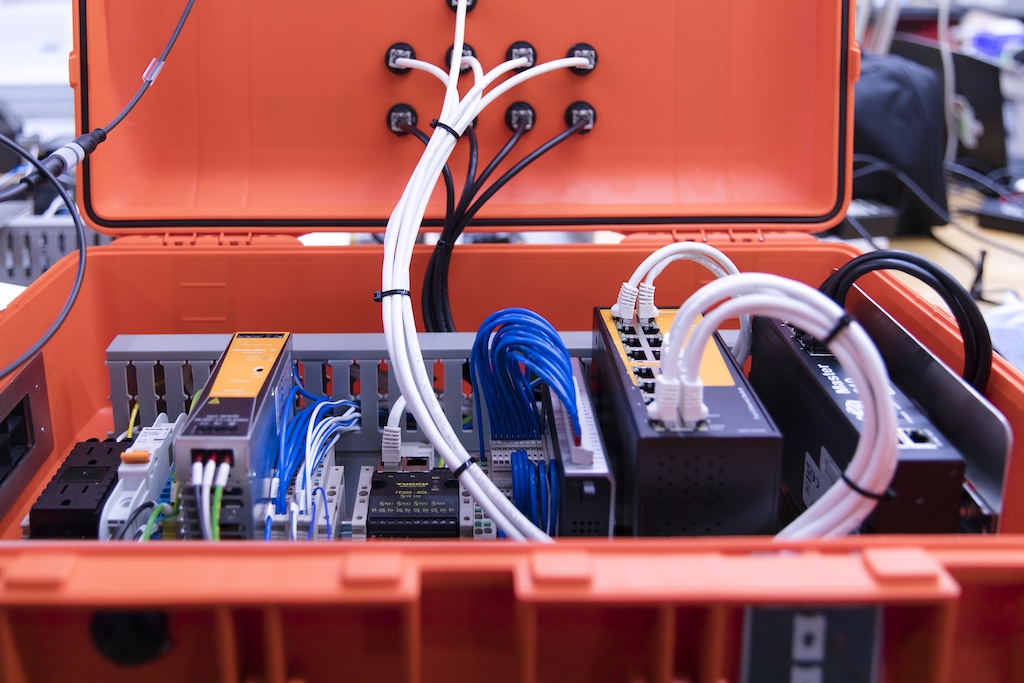

The AIQ controls systems have been built to last for many years. Our standard panel options are packed full of the latest name brand pro series hardware. Each solution is hand-built in our shop with the upmost care given to quality assembly practices. PLC controls needed, no problem. We service most major brands including Allen Bradley, Simens, and Horner OCS to name a few. Need the data served up to your in house SCADA system, no problem. Our team of experts will get you the visualization of your data quickly and efficiently.

Need to go mobile? Our Go-Box controller houses an entire multi-sensor control platform. This system is perfect for your factory technicians needing to setup a precision frame on the bench, or for your R&D group wanting to explore new capabilities embedded in our technology AIQ arch solution. Whatever the need may be, rest assured the EX31 Automation factory Virginia has the expertise needed to measure your products.

Universal Precision Frames | EX31 Factory Industrial Automation Company Virginia

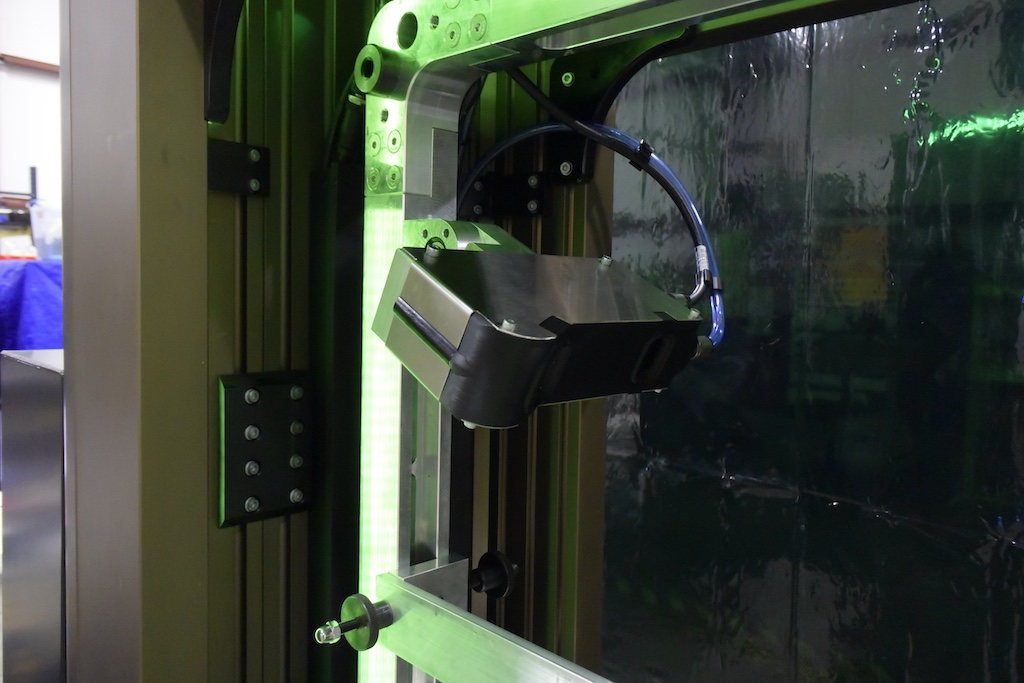

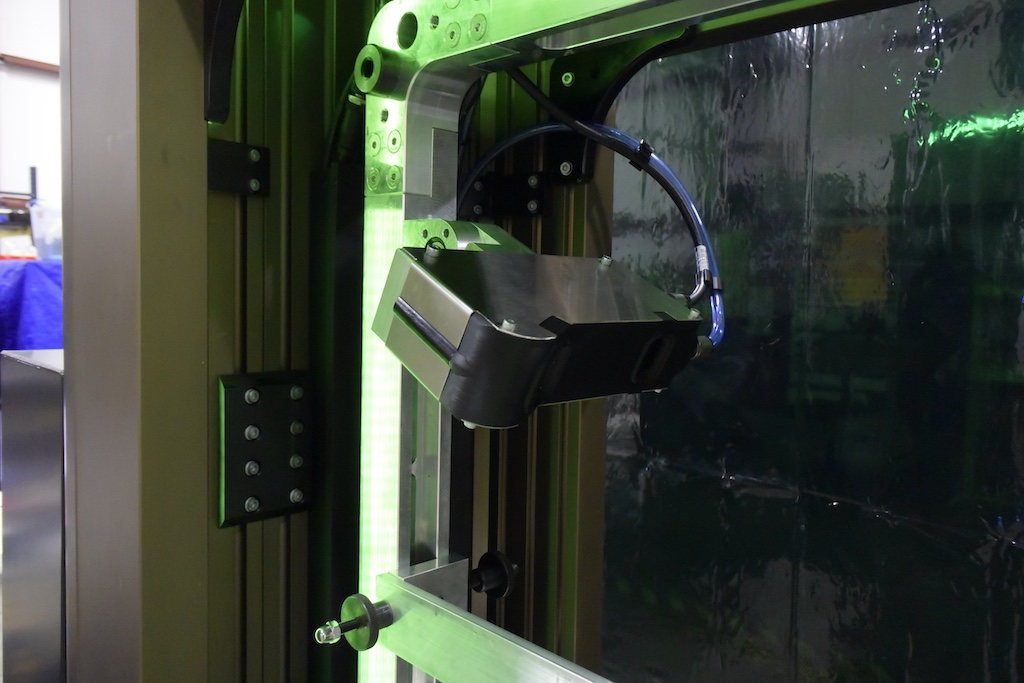

The AIQ Universal Frame consists of a few major components. These three can be configured in a variety of ways to give you the most flexibility in building an effective measurement solution. We originally built this platform for multi-sensor ring layouts, and by default, our precision frames also work great for single sensor applications and more.

First of the three components is the frame members. These are typically configured in an arch shape, or even a single cross bar, but however needed they can be quickly assembled and can be utilized with corners or end bars for mounting the precision frame.

Second, once you have a configured frame, you will need to add a Pivot Hinge for each sensor. These will allow you to quickly re-position your sensor(s) to an optimal location and angle, that will allow you to almost eliminate any occlusions in your vison field of view.

Last but not least are the Go-plates. These billet aluminum plates enable you to have a great mounting surface for your sensor, and are the last key component for alignment of your sensor emitter lines. We even have options for utilizing multiple same family sensors on a single frame to enable data collection at the precision you require where you need it most.

Fixed Precision Frames

For the more dedicated configurations, our fixed precision frames are the best choice. These allow our clients to have both the flexibility in design but blended with a limited amount of adjustment for maintaining consistent results. At EX31 Industrial Automation company Virginia, we strive to provide you with the best solutions possible. See our catalog pages below for additional information on each component.

AeroPurge GoCover Kits

Our latest complimentary systems offering is the AeroPurge product series. These are designed to keep your Gocator clean using dry, clean compressed air. Too often the issues that most of our customers face is around keeping camera lenses clean. We have spent the last few years developing this product line and are excited to see how well we can enable our customers to win by achieving higher uptime in your manufacturing process. Have an issue keeping your sensor clean? Contact us today for a demonstration system. Maybe test before you buy.

AeroPurge | Operational Modes

The AeroPurge GoCover series is designed to keep your Gocator lenses free from debris. It uses pneumatic pressure to operate in two modes:

Mode 1: Continuous Clean – Feed the cover assembly with clean dry air and maintain positive pressure area above both lenses. This keeps most small foreign matter off of your emitter and receiver lenses.

Mode 2: Purge – positive air not enough? Add in a quick burst of higher pressure air for maintaining the best possible clean sensor faces.

Mounting the AeroPurge Cover

Our standard Gocator based AeroPurge cover attaches to sides of the GO-Plate. The three different designs will blow off most any dust and tiny debris to the side of your choosing. If you needed to look up from the bottom with three sensors, you can easily configure them with Left, Center, and a Right blow off nozzle keeping all three of your sensors clean and not blowing dust back and forth.

Check out our video demos and system performance testing.

Alternate AeroPurge Applications

Our AeroPurge product line is continuously expanding in its range. Contact us today and see if we have a solution to keep your automation sensors clean from debris.

PDF – Frame Members – Cross Bars